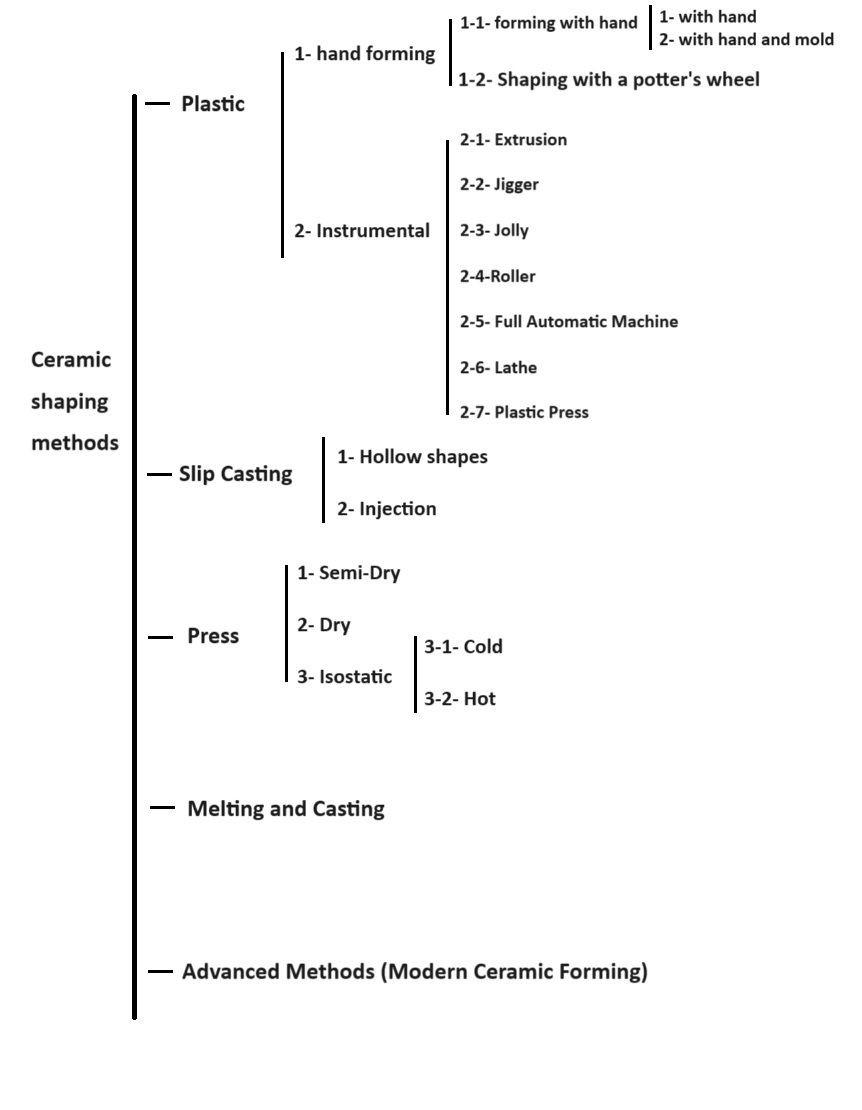

Ceramic raw materials have a high melting point compared to metals. for this reason, the melting and casting method which is the most common method of making glass and glass products and is also used in the manufacture of most metal artifacts, is less used in ceramics, because ceramic raw materials have different properties that affect Various methods have been used to shape their base.

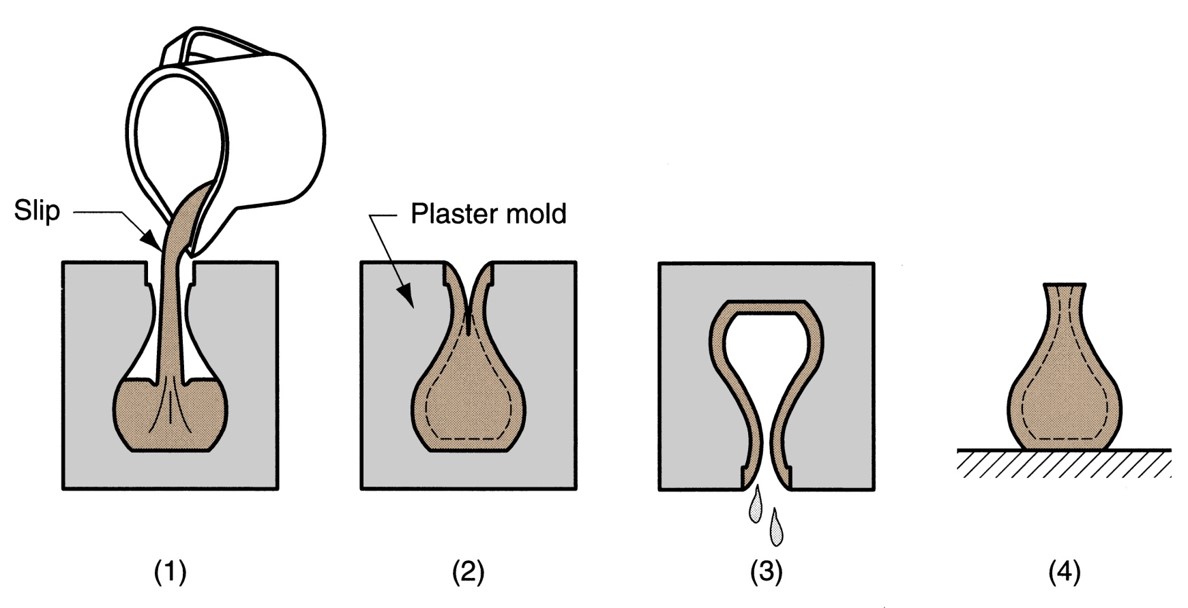

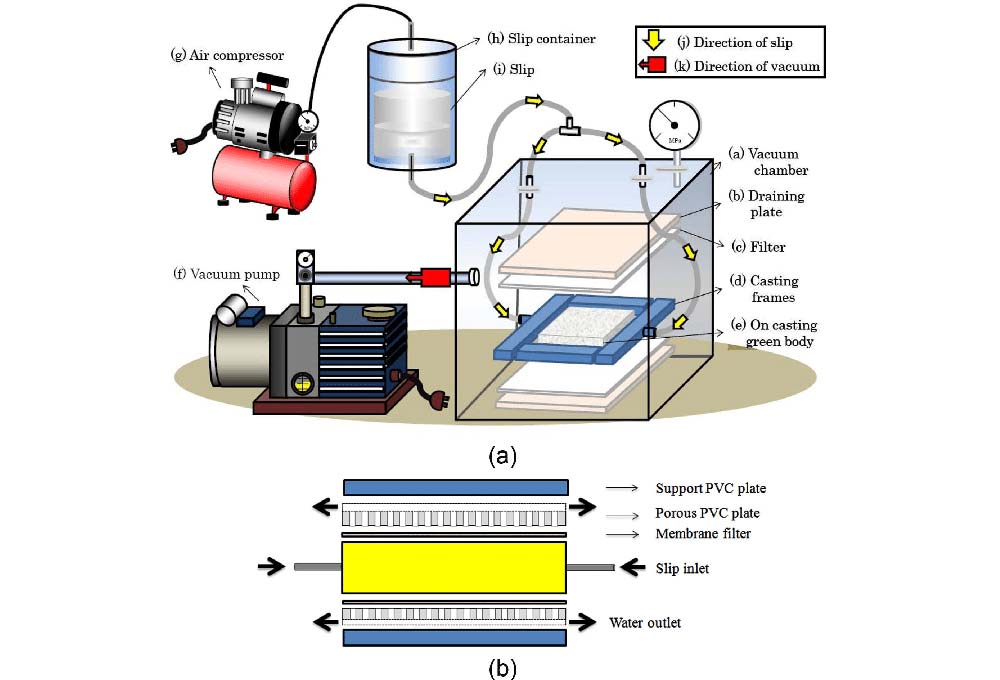

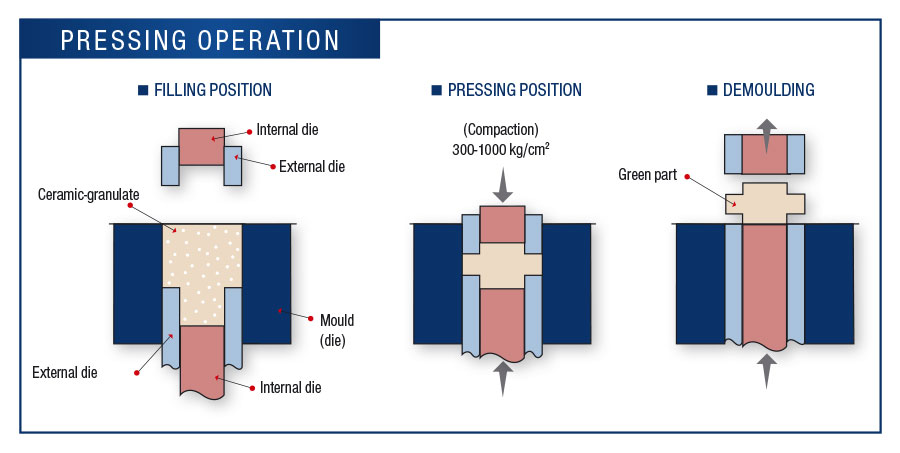

For example, the ability to form a mixture of clay and water depends on its water content. with 50 percent water, a slurry will be ready which can fill a mold’s corners simply with needed pressure.

When we reduce the amount of slurry water until it turns into mud. The pressure required to form and transform the product increases, and to convert it into a wet powder, this pressure increases dramatically.