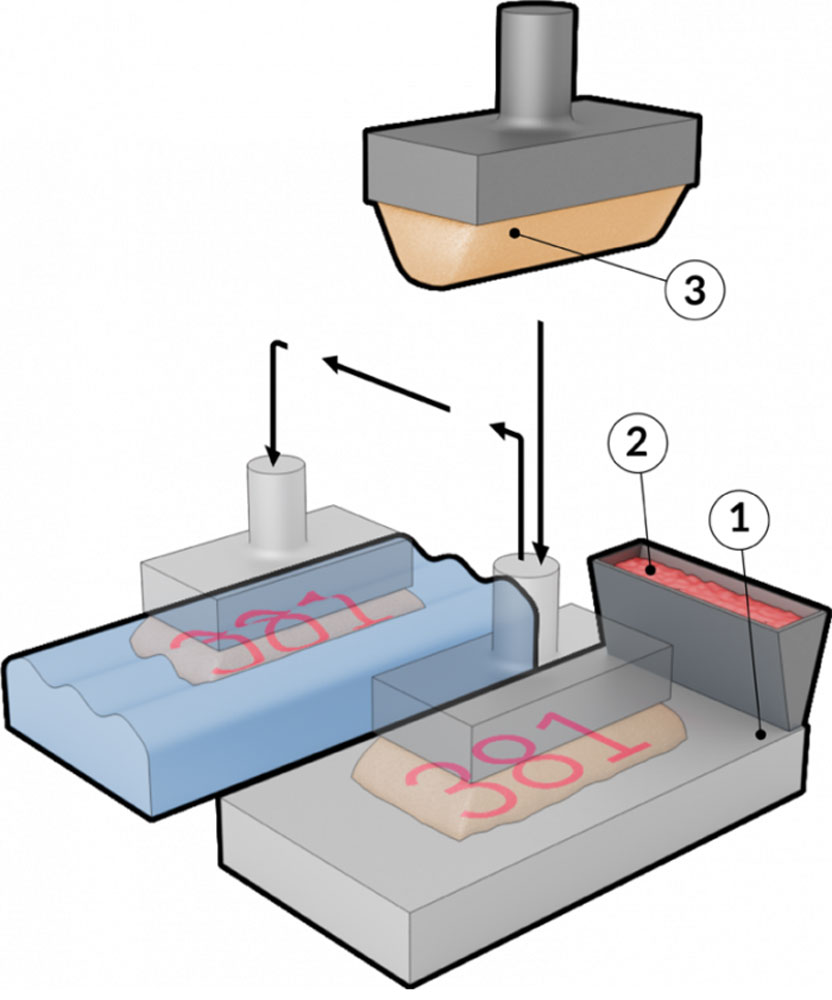

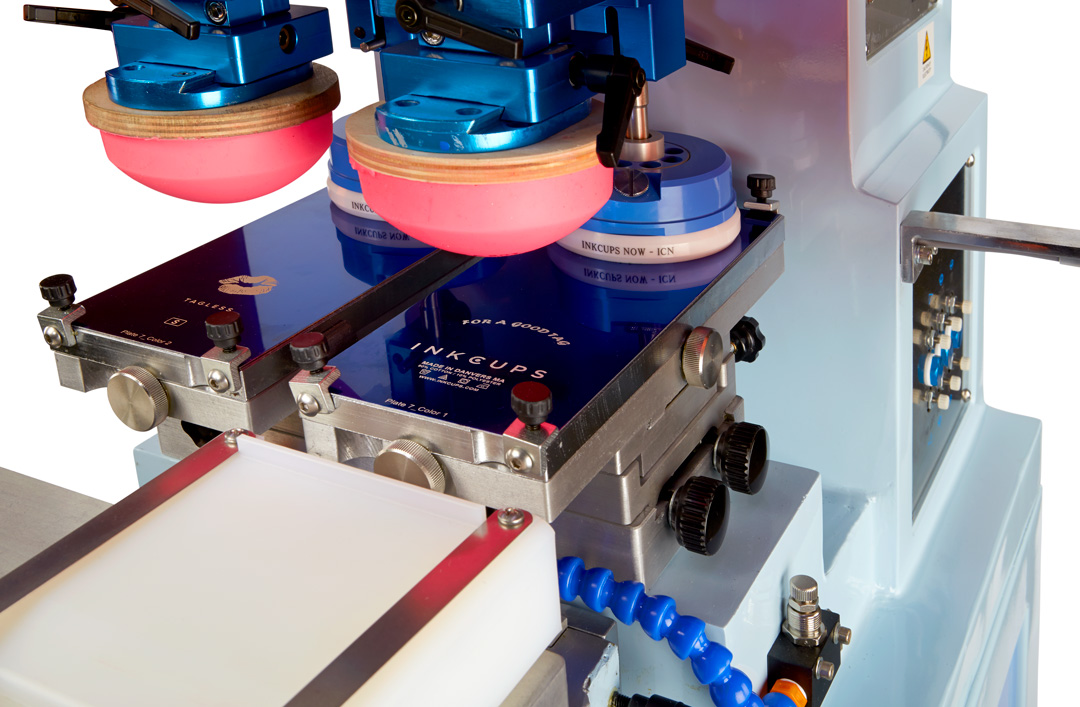

Pad printing, also called temography, is a printing process that can transfer a 2D image to a 3D object. This is done using an indirect offset printing (gravure) process, which involves transferring the image from the stereotype through a silicone pad to a three-dimensional surface such as a plate or bowl.

Pad printing is usually used to print on products that are difficult to print on normally. This technique is used in many industries, including medicine, automobiles, advertising, clothing and electronic objects, as well as household appliances, sports equipment, toys and ceramic dishes.

It can also be used to apply functional materials such as conductive inks, adhesives, paints and lubricants.

The unique properties of the silicone pad allow him to lift the image from the flat screen and transfer it to different surfaces such as flat, cylindrical, spherical, angled, textured, concave or convex surfaces.