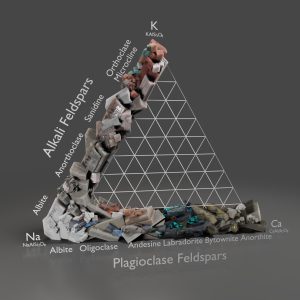

a) PRIMARY RAW MATERIALS

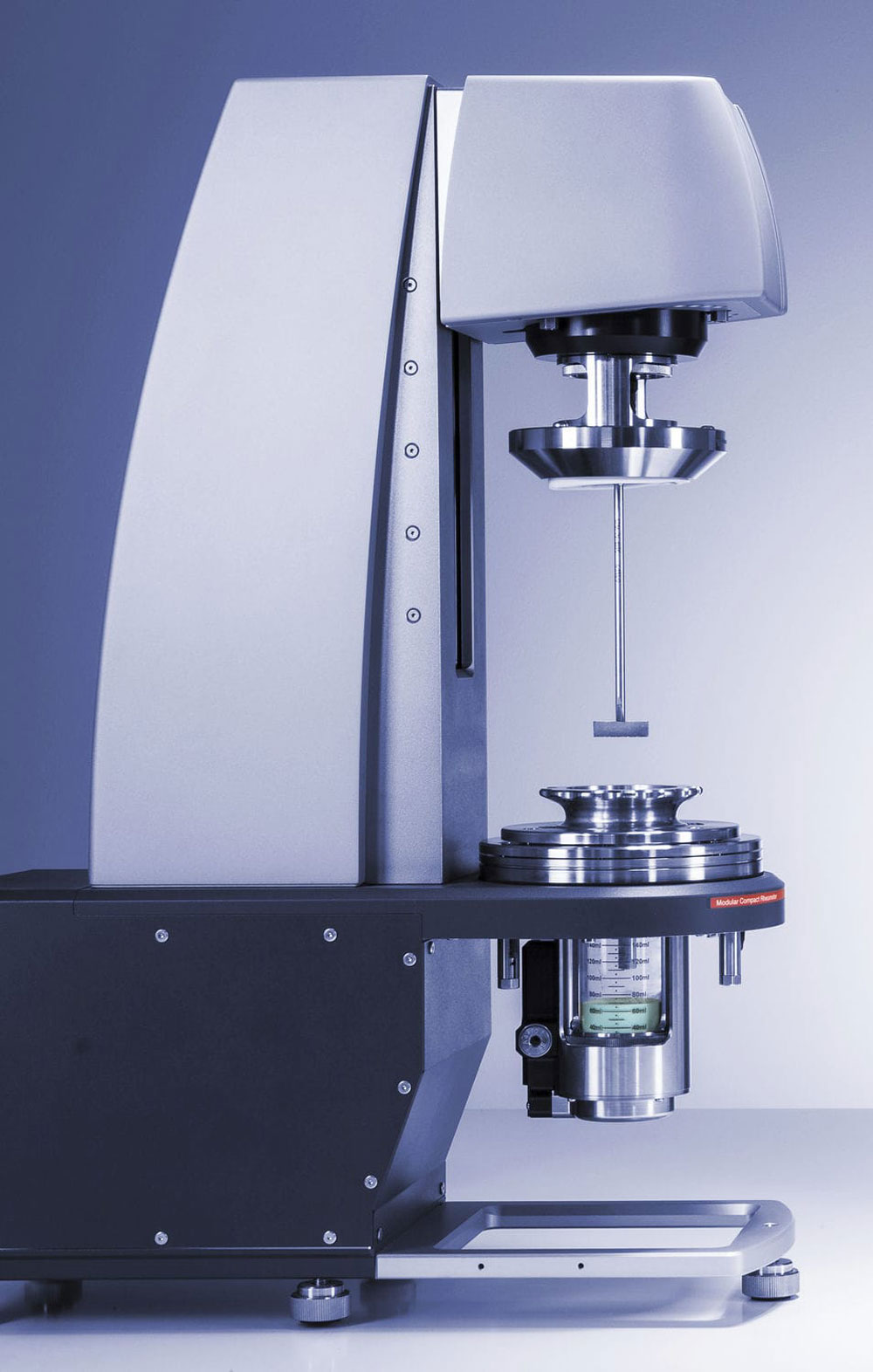

Even if they are carefully and methodically chosen, raw materials (especially clays) are natural products and for their very nature can undergo variations that cannot always be controlled. Specially if we consider that the stocks are constantly and frequently restored. The change in the level of clays’ plasticity (that, as we know, also affects the mechanical resistance values of raw tiles), for example, may promote significant variations of the ceramic mixture’s rheological features. Fluctuations of the humidity may similarly modify the viscosity values, affecting at the same the density values. In the case of modifications of the chemical and/or mineralogical composition of the raw materials, it would be hard and difficult to trace the causes of the rheological modification utilizing chemicals or X-ray analysis. In fact, in some cases, even these strategies are not able to give you accurate answers.

b) SECONDARY RAW MATERIALS

Sometimes, even the addition or variation of the chemicals within the slurries (both organic and inorganic), can lead to variation in the rheological behavior. Even if they are necessary for the proper development of the process, their use – regardless of whether they are binders or plasticizers – should always be preceded by rigorous analysis within the lab. The same applies to variations or additions of sludges, glazes, or recovered materials deriving from other production departments: even these materials should be previously checked, to prevent their possible impact on the barbottina’s rheology values.

c) GRINDING WATERS

The contents (or ingredients) of grinding water are usually difficult to define. The current trend is to recover inside the grinding waters, the wastes produced within the company, also adding in some cases the waste of other and external producers. This attitude offers reasonable help to environmental problems but at the same time can negatively affect the rheology of the slurry, promoting flocculation phenomena. Many studies have shown that very high conductivity values of flocculating metal ions, organic matters, and acid pH may significantly worsen the viscosity and flow limit of the barbotine: regardless of the consequences, the most important problem is the extreme variability of the water’s features involved in the milling process. This is the reason why it should be important to take some essential preventive actions:

- Stock the water in large tank, to reduce the range of fluctuations

- Check the water’s density (their dry content), avoiding density issues within the slip

- Check the pH value and the electrical conductivity of the water, adjusting the parameters when necessary. A too-acid pH, for example, may worsen the viscosity and the flow of the barbotine

- Carefully consider the water deriving from the purifiers: even if they seem clear and clean, they can hide pitfalls, such as an important amount of flocculants

- Check and properly manage possible bacterial contaminations that can increase the water’s electrical conductivity

d) DEFLOCCULANTS

The proper rheology of the barbotine may also be affected by a wrong dosage of the ceramic deflocculant (manual or mechanical). Each of them, according to the application conditions, is marked by specific features that differently impact the rheological values, such as the viscosity. Each of them can work within a different range that can be considered appropriate or not. This is the reason why (even if the addition within the slip is usually developed utilizing electro-mechanical systems) it is recommended to periodically check the quantity in use.

e) GRAIN SIZE

The grain size of the barbotine is surely related to rheological parameters. To put it simply: all other things being equal, a high amount of residual matter stands for low viscosity values and, vice versa, a low amount stands for high or very high viscosity values.

What does that mean?

The sieving trial is usually developed utilizing a dense mesh screen. In the case of the high amount of residual matter, it means that the grinding process has produced a barbotine marked by a coarse particle size that, in turn, results in greater flow and lower viscosity values. On the other side, when the milling process produces a smaller grain size, particles are marked by a lower wettability. This means that we are facing higher viscosity values.

f) TEMPERATURE

The slip’s temperature – during the grinding process – is another element that must be carefully considered since it may affect the proper dispersion of the suspended particles. The temperatures influence the deflocculants’ efficiency during the grinding and dispersing processes, affecting therefore the rheological parameters of the suspension. In general, high temperatures promote a better grinding process and, instead, too high or too low temperatures may decrease the production yield.

g) GRINDING BODIES

The number and the grain size of the grinding bodies are the basis of a proper grinding process, also affecting the proper conditions of the mill finish. Checking and adjusting these parameters is surely useful, if not necessary. However, even a little attention does not usually cause sudden changes in the slips’ rheology values. It can only lead over time to a worsening trend of the milling process.